Gas pipeline installation for commercial heating demands meticulous planning, adherence to strict regulations, and a focus on safety and efficiency. Commercial and Industrial premises rely heavily on gas process heating systems, making the installation process critical for ensuring uninterrupted operation and compliance with legal requirements. The key aspects of gas pipeline installation for commercial heating in the UK are:

Planning:

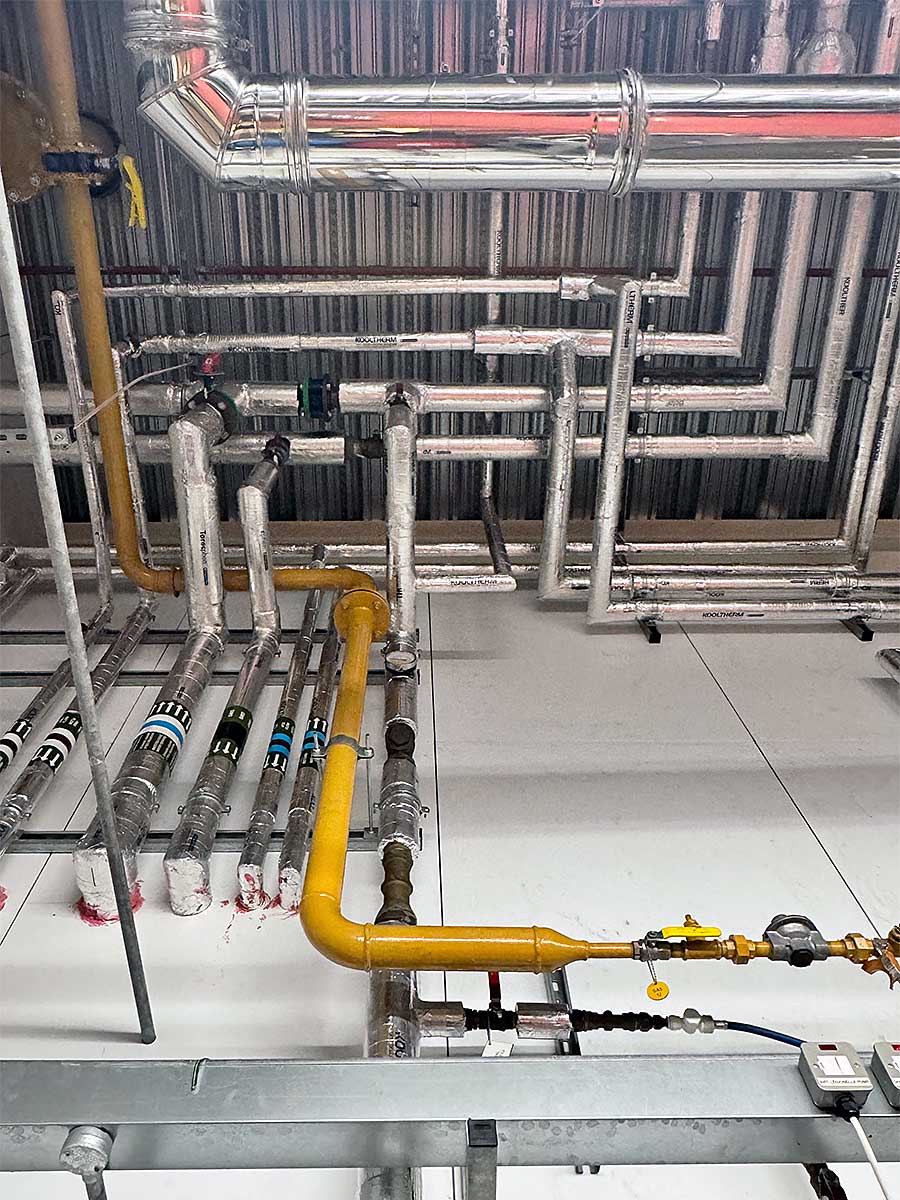

Effective planning is essential for successful pipeline installation for commercial and process heating systems. This involves conducting a thorough site survey to assess factors such as building layout, existing infrastructure, gas supply requirements, and safety considerations. Designers must collaborate closely with architects, engineers, and building owners to develop a comprehensive plan that meets the specific needs of the commercial establishment.

During the planning phase, considerations such as the routing of pipelines, location of gas meters, and accessibility for maintenance and repairs must be taken into account. Additionally, designers must consider future expansion plans and ensure that the installation complies with local building codes and zoning regulations.

Regulatory Compliance:

Compliance with regulatory standards is paramount in the installation of gas pipelines for commercial heating in the UK. Gas installations must adhere to regulations set forth by organizations such as the Gas Safe Register, Health and Safety Executive (HSE), and British Standards Institution (BSI). The Gas Safety (Installation and Use) Regulations 1998 outline legal requirements for the safe installation, operation, and maintenance of gas appliances and pipelines.

Designers and installers must ensure that all aspects of the installation, including materials selection, pipe sizing, and ventilation, comply with relevant regulations. Failure to comply with these regulations can result in legal penalties, fines, and potential risks to the safety of occupants and property.

Safety Measures:

Safety is a top priority in the installation of gas pipelines for commercial heating systems. Designers must implement robust safety measures to prevent accidents, leaks, and other hazards. This includes incorporating features such as leak detection systems, pressure relief valves, emergency shut-off valves, and adequate ventilation.

Gas pipelines must be installed by qualified professionals who have undergone training and certification in gas safety. Regular inspections and maintenance procedures should be established to ensure the continued integrity and safety of the pipeline network. Additionally, emergency response plans should be developed to outline procedures for addressing gas leaks and other emergencies.

Efficiency Considerations:

Efficiency is crucial in commercial heating systems to minimize energy costs and environmental impact. Designers should prioritize the selection of energy-efficient equipment and materials, such as condensing boilers, high-efficiency heat exchangers, and insulated piping.

Proper sizing and layout of gas pipelines can also contribute to efficiency by minimizing energy losses and optimizing system performance. Hydraulic calculations should be performed to determine the optimal pipe diameter and layout to meet the required flow rates and pressure levels.

To summarise, the installation of gas pipelines for commercial heating requires careful planning, regulatory compliance, safety measures, and a focus on efficiency and environmental sustainability. By adhering to strict regulations, implementing robust safety measures, and prioritizing efficiency and sustainability, designers and installers can create reliable, safe, and energy-efficient gas heating systems that meet the specific needs of commercial establishments while minimizing environmental impact.

At Fairburn, we have considerable experience of installing pipework; from relatively basic designs to the most complex. All our installations are completed safely with a strong focus on the quality of work. If we haven’t created the design, we will check that the specification is correctly sized and we test all our work thoroughly, complying with IGE UP1 Edition 2 and IGE UP2 Edition 3 standards.

We believe it makes perfect sense to use the same company for installation and maintenance of pipework – detailed knowledge of the installation work can save time and money on maintenance.

Every pipework installation project is executed to industry best practice standards including:

- Rigorous design review

- Accurate pipe sizing to IGE/UP/1 Edition 2 and IGE/UP/2 Edition 3

- Fast, safe and professional installation

- Testing & purging

- Live pipework commissioning

- Handover