For many businesses, process heating systems are characterised by unexpected failures, unplanned breakdowns, unpredictable and uncontrolled repair time all combining to create spiralling downtime costs and disruption.

To make matters worse, an increasing number of customers are seeking to reduce inventory costs and asking their key suppliers to commit to continuity of supply with substantial penalties and even loss of business for failures.

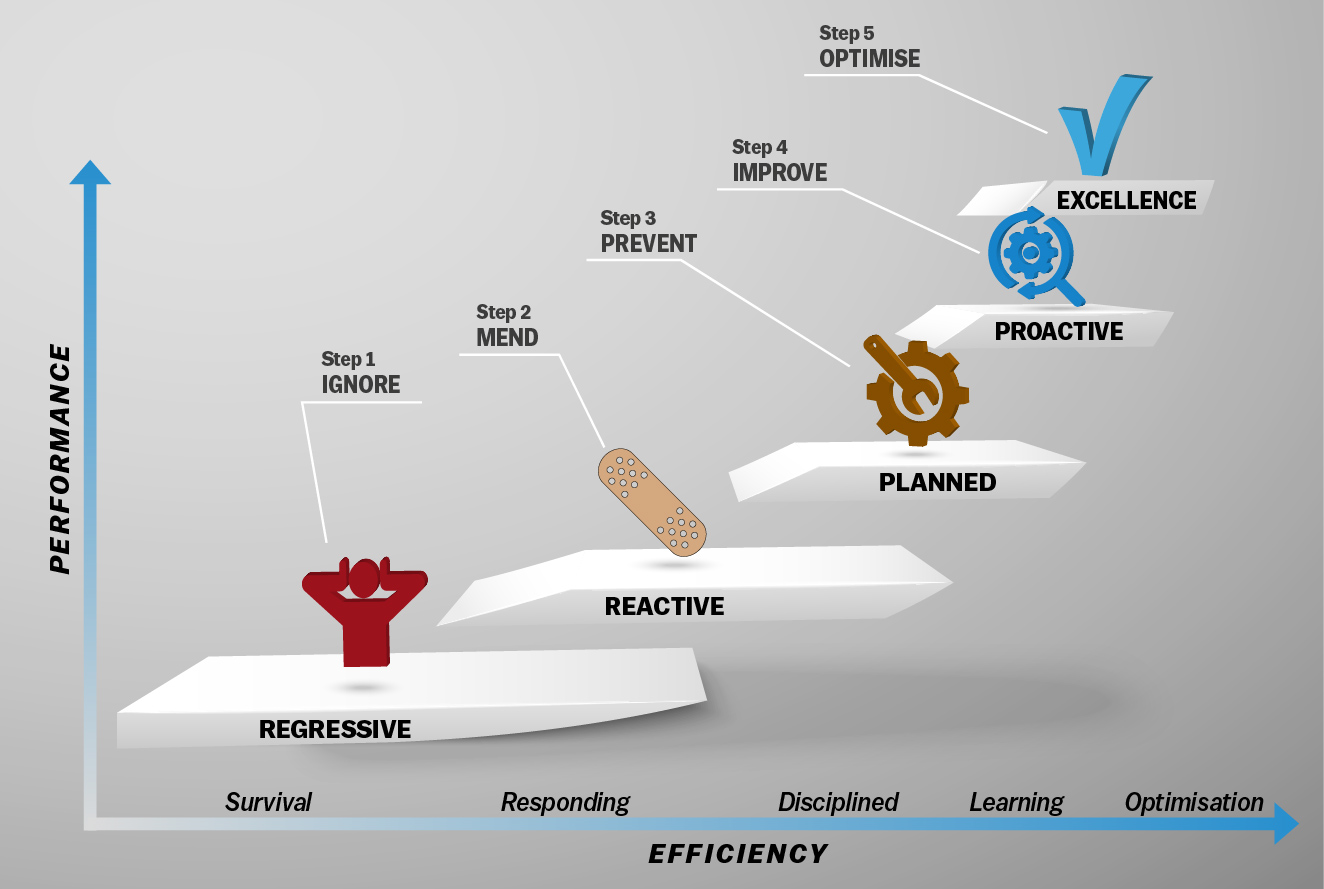

At Fairburn Heating Solutions we believe process heating should never cause downtime. We help our customers move from this chaotic situation to a position of excellence where their process heating system is continually improved and optimised, making a positive contribution to business success. We achieve this by following our 5 step Asset Management Excellence Journey.

Step 1 is where many clients start, often described as the “If it ain’t broke, don’t fix it” approach. Maintenance is ignored until an item breaks, when a fix is then organised. The consequences of this approach are unexpected failures, poor reliability, safety issues, and unpredictable output availability. Whilst this may sound (and be) and undesirable state of affairs, many businesses have become accustomed to this as the status quo, and are unaware of the opportunity to move to a better approach. In our next blogs, we will cover the remaining steps, but if you can’t wait, you can read more and download our White Paper or call us on 01886 358025.