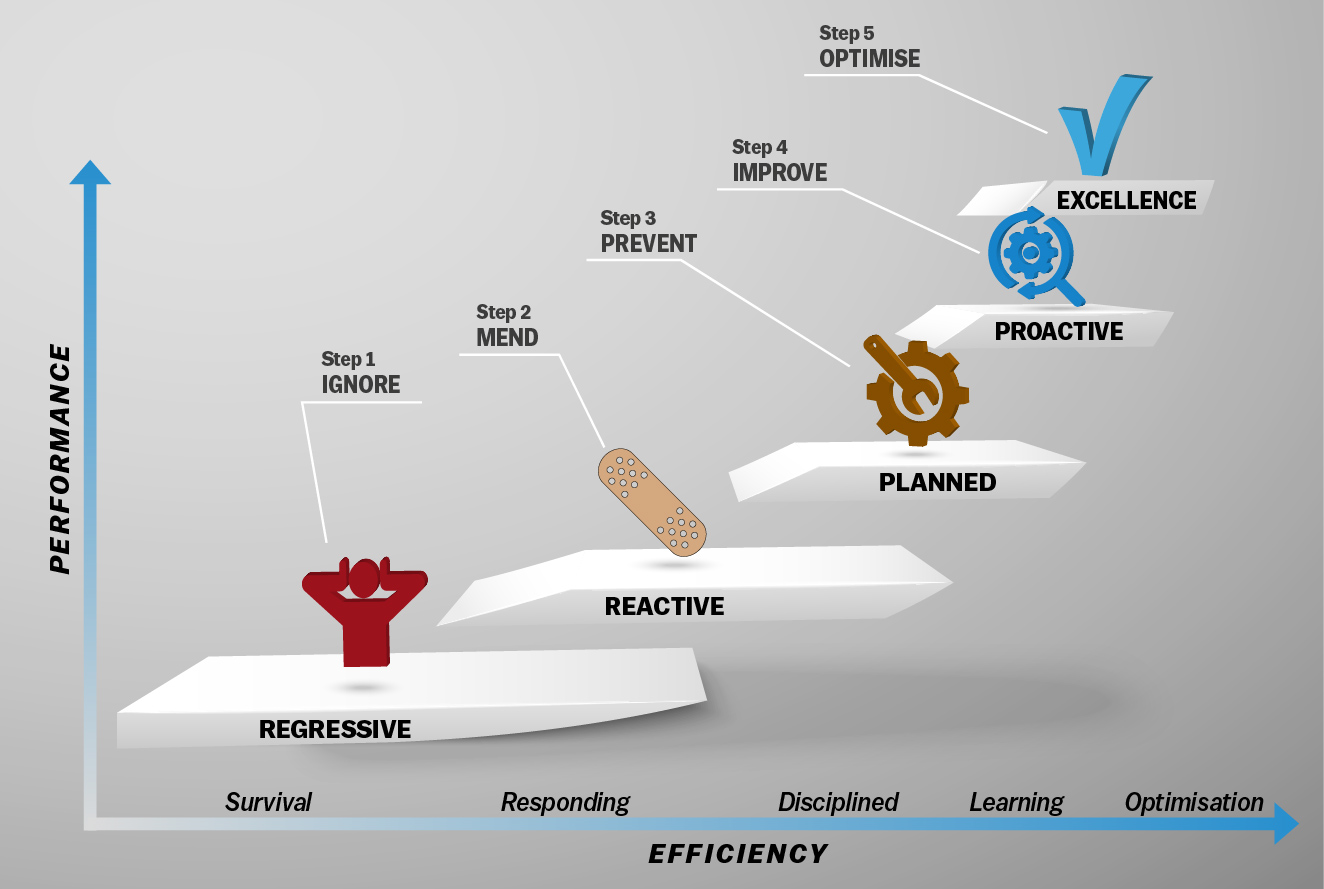

When Mowi ASA, the world’s leading seafood company and largest producer of Atlantic salmon had problems with their salmon feed dryers they contacted Fairburn Heating Solutions to see if we could help.

The company had been experiencing problems with the gas burners in the driers since they were originally installed. James Brown, one of our Senior Process Gas Technicians and Sam Harris our new process gas trainee visited the plant on the Isle of Skye to conduct a full service and fault find on the burners. They both completed the service, identified the problem, made the necessary adjustments and gave recommendations to the on-site team. The driers are now running in a fault-free manner.

Mowi were very pleased with the work done and have agreed to make Fairburn an annual service provider, putting their trust in our knowledge and expertise.

Commenting on the project, James said “a 1,000 mile round trip was a long way to go for the project, but the scenery when I got there more than made up. It’s great that we were able to fix the problem and that we’ve secured more work, but my colleagues are already offering to do the job in my place.”

If you have been putting up with persistent gas burner problems, give us a call on 01886 358 025, email us at totalsolutions@fairburnhs.com or use the contact form on this website and we’ll see if we can help.