Gas pipeline design for commercial heating demands careful attention to regulatory compliance, safety considerations, and efficiency to meet the specific needs of clients’ businesses while adhering to local standards and regulations such as IGE/UP/1 and IGE/UP/2

Regulatory Compliance:

In the UK, gas heating systems for commercial use must comply with regulations set forth by organizations such as the Health and Safety Executive (HSE), Gas Safe Register, and British Standards Institution (BSI). These include:

- Gas Safety (Installation and Use) Regulations 1998

- IGE/UP/1 and IGE/UP/2 standards

- BS-EN ISO 13577-2;2003 Industrial Furnaces and associated processing equipment – safety part 2 combustion and fuel handling systems

The regulations outline the legal requirements for the safe installation, operation, and maintenance of gas appliances and pipelines. Compliance with these regulations to mitigate risks and ensure the safety of occupants and property is a critical aspect of pipeline design.

Safety Considerations:

Safety is paramount in the design of gas supply pipelines. Implementing robust safety measures such as leak detection systems, pressure regulation devices, and emergency shut-off valves is essential to prevent accidents and protect personnel and assets. Regular inspections and maintenance procedures must be established to ensure the continued integrity and safety of the pipeline network.

Efficiency:

Efficiency is a key consideration in commercial gas heating systems to minimize energy costs and environmental impact. The gas pipeline design should prioritize the selection of energy-efficient equipment, such as condensing boilers and high-efficiency heat exchangers, to maximize energy utilization and reduce emissions. Additionally, optimizing the layout and sizing of pipelines can minimize energy losses and improve overall system performance.

Material Selection:

Choosing the appropriate materials for gas pipelines is critical to ensuring durability, corrosion resistance, and longevity. Common materials used in the UK include steel (mild and stainless), copper, and polyethylene. Steel pipes are suitable for high-pressure applications and outdoor installations but require corrosion protection. Copper pipes offer excellent corrosion resistance and are often used for indoor applications. Polyethylene pipes are lightweight, flexible, and resistant to corrosion, making them ideal for underground installations.

Design Considerations:

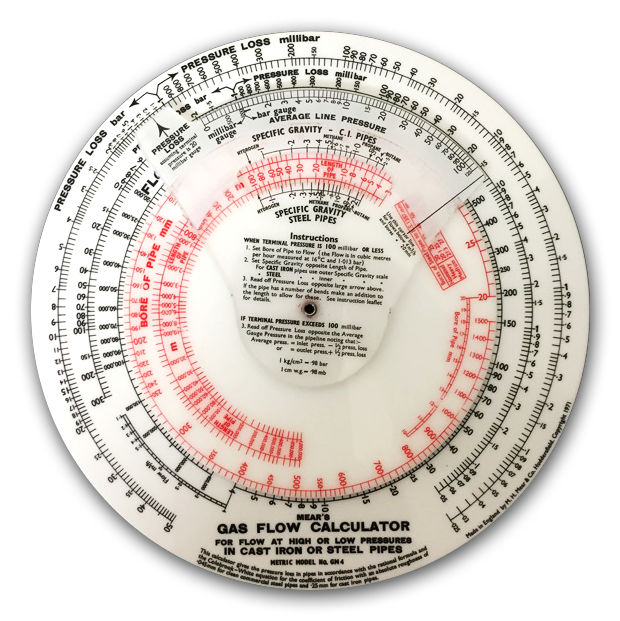

The commercial heating gas pipeline design mut take into account factors such as the size of the premises, peak demand, and future expansion plans. Hydraulic calculations are performed to determine the optimal pipe diameter and layout to meet the required flow rates and pressure levels. Designers should also consider factors such as accessibility for maintenance, emergency access, and compliance with building regulations and zoning requirements. A good pipeline design will also make installation easier.

To summarize; designing gas pipelines for commercial heating in the UK requires a comprehensive approach that addresses regulatory compliance, safety considerations, efficiency, and environmental sustainability. By adhering to local regulations, implementing robust safety measures, optimizing system efficiency, and prioritizing environmental sustainability, designers can create reliable, safe, and energy-efficient gas heating systems that meet the needs of commercial businesses while minimizing environmental impact.

Fairburn Heating Solutions has considerable experience in pipework design and helping clients define exactly what they want. Converting what we want to achieve into a detailed design brief can be a challenge, but we make sure we understand the requirements properly and create a practical design to meet them.

All our pipework designs conform to industry best practice and we adhere to the Royal Academy of Engineering six principles for designing engineering systems:

- Debate, define, revise and pursue the purpose of the pipework

- Holistic thinking – the pipework design is only as good as the weakest point

- Disciplined procedures to minimise the possibility of errors

- Creative – thinking logically and laterally

- People focus – how easy will it be to operate?

- Project and relationship management

Well designed pipework will also make pipework installation and future pipework repair easier